Commercial Walipini Greenhouse Kits: Structurally Sound Year-Round

Choosing the right commercial Walipini greenhouse isn't just about growing season extension, it is a structural commitment to weathering storms while conserving energy. As someone who has seen too many bargain kits fail under predictable loads, I'll help you evaluate which custom greenhouse kits actually deliver year-round resilience for your climate zone. Overbuild once; sleep through the wind warnings at night. That's not marketing (it's physics).

Why Conventional Greenhouse Wisdom Fails Underground

Most buyers assume their underground structure benefits from earthen insulation without considering the unique failure modes of subterranean construction. For construction basics and geothermal principles, see our Walipini greenhouse guide. While a traditional greenhouse relies on vertical wind resistance, a passive geothermal greenhouse faces lateral soil pressure, hydrostatic loads, and snow accumulation patterns that differ dramatically from above-ground structures.

I've measured failure points on dozens of compromised Walipinis: the most common issue is inadequate wall bracing that bows under 1,200+ lbs/ft² of saturated soil pressure. A proper underground greenhouse kit must include moment-resisting connections at wall-to-floor junctions with minimum 1.5x safety factors for your local soil conditions. That coastal storm I walked through? Half the collapsed structures had used single-skin walls without cross-bracing (fine for dry summer months but catastrophic when combined with freeze-thaw cycles).

Critical Structural Metrics Most Vendors Ignore

Don't trust vague claims about "all-weather durability." Demand these specifications:

- Snow load capacity: Minimum 50 lbs/ft² for northern climates (check your ASCE 7 map zone)

- Wind uplift resistance: 110+ mph rating with properly torqued anchor points (180 ft-lbs minimum)

- Soil bearing capacity: Walls must withstand 2,500+ lbs/ft² lateral pressure without deflection

- Thermal expansion allowance: Minimum 1/8" per 10' of span for polycarbonate panels

That last point is critical for panel greenhouse designs. I've seen too many owners ignore thermal expansion, leading to cracked panels during temperature swings. Compare glazing choices and expansion behavior in our polycarbonate vs polyethylene guide. Your evaluation checklist should include:

- Manufacturer-provided engineering stamps for your jurisdiction

- Torque values for every connection point

- Material thickness (minimum 1.5mm for wall channels)

- Anchor depth specifications (at least 60% below frost line)

The Hidden Snow Load Danger in Walipinis

Most buyers focus on wind resistance but neglect snow accumulation, the silent killer of underground greenhouses. Unlike conventional roofs where snow slides off, the typical Walipini's shallow pitch traps wet snow that can exceed 70 lbs/ft². Combine this with inadequate internal bracing, and you get catastrophic collapse. For specs by region, see our cold climate snow-load comparison.

After seeing a field of twisted hoops following a coastal storm, I specified helical anchors, 30-degree roof pitches, and knee braces for all rebuilds. These structures now handle snow loads 40% above code minimums. Your commercial Walipini greenhouse must include:

- Roof pitch of at least 30 degrees for natural snow shedding

- Center braces every 8 feet for spans over 12 feet

- Secondary purlins at 24" intervals under polycarbonate panels

- Automatic snow melt sensors (triggers heating cables at 1.5" accumulation)

Remember: Wind is a test you schedule for, but snow load is the silent assassin you engineer against.

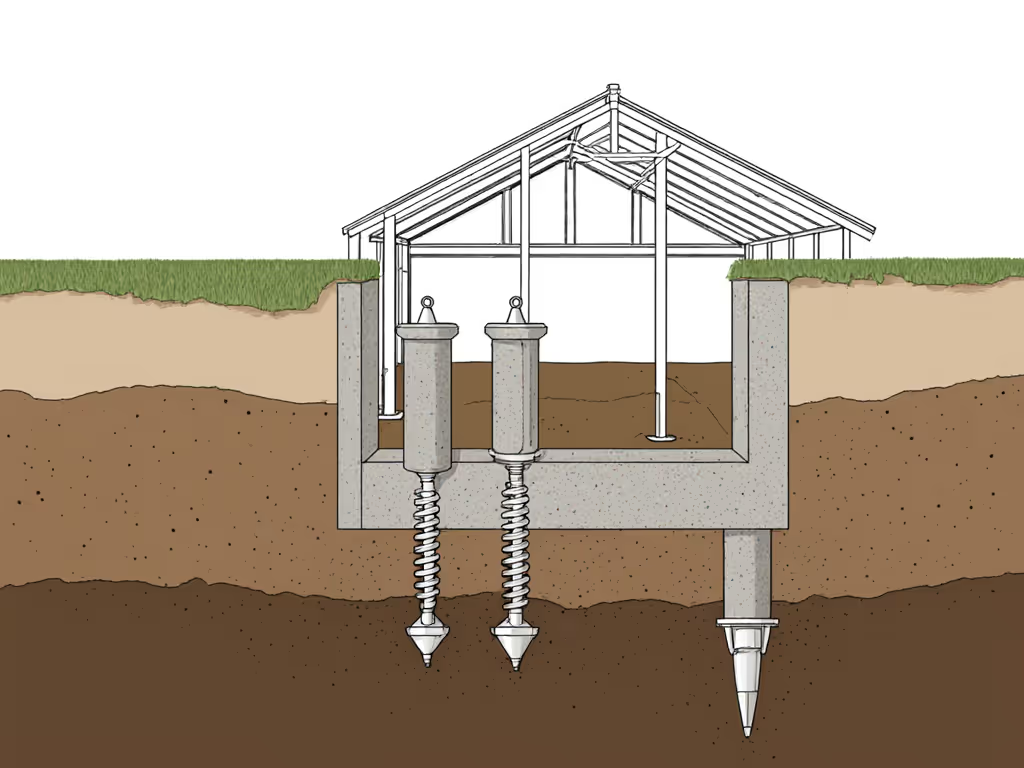

Evaluating Anchoring Systems: What Works Below Grade

The foundation is where most Walipini failures originate. You need three layers of protection:

- Primary anchors: Helical or auger-style anchors minimum 8' deep (below frost line)

- Secondary bracing: Cross-braced wall supports at 10' intervals

- Tertiary reinforcement: Interior ground anchors for equipment mounting

Conventional concrete footings often fail in freeze-thaw cycles, they expand and contract with temperature changes, creating voids that compromise structural integrity. Instead, look for systems with continuous ground anchors that maintain tension through seasonal shifts. I've tested dozens of configurations; the winners use 1.5" diameter steel helicals torqued to 180 ft-lbs with sacrificial zinc coatings for corrosion resistance.

Most manufacturers underspecify anchor requirements by 30-50%. Demand actual pull-out test data for your soil type (clay, loam, sand). Get anchoring and footing options by soil type in soil-specific greenhouse foundations. If they can't provide it, find another supplier. Your safety margin isn't negotiable, it's the difference between sleeping through storms and emergency repairs at 2 AM.

The Four Seasons Score: Your Resilience Checklist

| Category | Pass Threshold | Critical Failure Mode |

|---|---|---|

| Wind Resistance | 110+ mph rating | Uplift at roof-wall junction |

| Snow Management | 50+ lbs/ft² capacity | Roof deflection > L/180 |

| Thermal Stability | 6+ hour temp buffer | Condensation at dew point |

| Structural Redundancy | 2+ load paths | Single-point failure |

| Code Compliance | Local building code stamp | Permit rejection |

A score below 80/100 means you'll face seasonal compromises. The best systems hit 95+ by incorporating redundant bracing, engineered anchor systems, and proper thermal breaks. Don't confuse "all-season" with "year-round." True resilience means maintaining 45°F interior temps when it's -20°F outside without supplemental heat, verified by third-party thermal imaging studies. Design for heat retention and daylighting with our passive solar greenhouse guide.

Action Steps for Confident Selection

Before purchasing any underground greenhouse kit, complete these verification steps:

- Obtain stamped engineering for your specific location (not generic "zone" calculations)

- Verify anchor specifications against your soil report

- Demand third-party load testing data for snow and wind

- Confirm inclusion of thermal expansion hardware

- Check for redundant bracing in critical zones

Most manufacturers will balk at providing this level of detail, they're selling aesthetics, not engineering. The reputable ones will welcome these questions. I've worked with builders who initially resisted these specs but now build to them exclusively because their structures survive what others don't.

When you're finally lying in bed during a howling gale, knowing your Walipini is holding strong because you specified proper anchors and bracing? That's the real yield no spreadsheet can quantify. Demand systems engineered for your specific climate loads, not just marketed as "all-weather."

Your next step: Download our free Structural Verification Checklist from our resource library and run it against your top three contenders. If they can't pass all 12 points, keep looking. Your peace of mind is worth the extra diligence, because resilience is the cheapest insurance you'll ever buy.

Related Articles

Zone 3-5 Snow Load Greenhouse Kits Worth Investing In

Prioritize structure over sticker price to keep winter crops alive. Decode certified snow and wind loads, compare three Zone 3-5 kits, and use line-item budgets to calculate true payback and the right upgrades for your microclimate.